Designing a digital clock requires a blend of functional engineering, electronics expertise, and aesthetic design to create a clock that is accurate, user-friendly, and visually appealing. Here are the key steps involved in designing a digital clock:

1. Define Key Features and Functions

- Purpose: Decide if the clock is for home, office, travel, or industrial use, as this will guide the design, size, and features.

- Core Functions: Determine the basic features, like time display, alarm settings, or additional functions (e.g., temperature display, countdown timer, calendar).

- Additional Features: Depending on the clock’s purpose, consider adding features like backlighting, snooze, projection, or smart connectivity (e.g., Bluetooth, Wi-Fi).

2. Select Display Type

- LED Display: Offers bright, clear visibility, especially in low-light settings. Ideal for indoor and bedside clocks.

- LCD Display: Consumes less power, making it suitable for battery-operated clocks. Great for travel or portable clocks.

- OLED Display: Thin, with deep contrast, OLED displays are becoming popular for high-end, sleek designs.

- E-Paper Display: Mimics printed text, consuming very little power and making it ideal for minimalistic, battery-powered designs.

3. Choose the Microcontroller or Chipset

- Clock IC: Choose a real-time clock (RTC) chip for high-accuracy timekeeping, essential for digital clocks.

- Microcontroller: If the clock has more complex functions like alarms, weather data, or connectivity, a microcontroller with sufficient memory and processing power is required (e.g., ESP32 for Wi-Fi-enabled clocks).

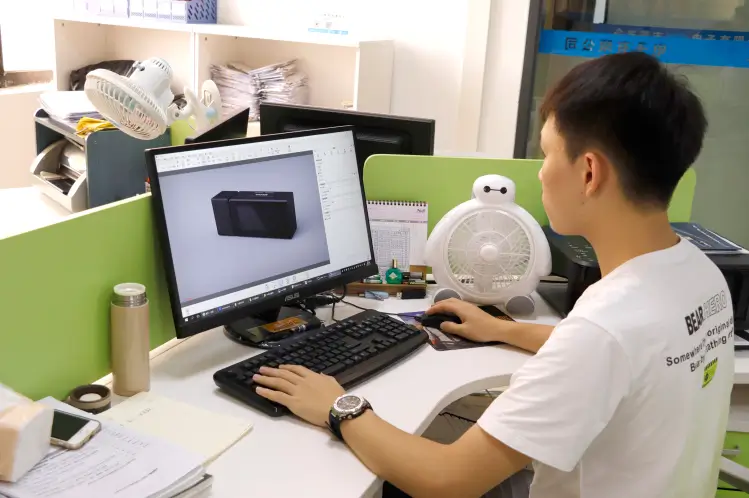

4. Design the PCB (Printed Circuit Board)

- Circuit Layout: The PCB design is crucial, as it connects the microcontroller, display, power source, and other components. Use PCB design software to layout the components and pathways.

- Component Placement: Place components in a way that minimizes interference and heat generation. Position the microcontroller and RTC chip close to the power source and display connections.

- Consider Battery Backup: For clocks that need to keep time during power outages, design space for a backup battery or capacitor.

5. Power Supply and Power Management

- Power Source: Decide between a rechargeable battery, AA/AAA batteries, or an AC adapter. Battery power is more convenient for portable clocks, while AC is better for stationary, power-intensive clocks.

- Power-Saving Features: For battery-operated clocks, consider power-saving functions like auto-dimming, standby mode, or timed backlighting.

6. Design the User Interface

- Button Layout: Ensure buttons are accessible and intuitive for setting time and alarms. Many clocks include an up/down interface with a dedicated “set” button.

- Touch Interface: For modern designs, consider capacitive touch controls for a sleek, button-free look.

- App Connectivity: For smart clocks, design a user-friendly app interface allowing users to control the clock settings remotely.

7. Design the Outer Casing and Aesthetics

- Material Selection: Choose materials based on durability and style. Options include plastic, metal, wood, or glass, depending on the intended look and market.

- Form Factor: Decide if the clock will be wall-mounted, desk-mounted, or portable. This affects size, shape, and weight.

- Aesthetic Features: Consider the overall color scheme, finish (matte, gloss, brushed), and style (modern, retro, minimalist).

8. Programming the Software/Firmware

- RTC Programming: The microcontroller software should read the RTC chip and keep accurate time, adjusting for user settings like alarms, snooze, and calendar.

- Additional Functionality: Program additional features like brightness adjustment, temperature display, or smart home integration if applicable.

- User Feedback and Testing: Conduct user tests to ensure the interface is intuitive, and adjust programming for any identified improvements.

9. Prototyping and Testing

- Build a Prototype: Create a functional prototype with a 3D-printed or CNC-machined casing, fully assembled PCB, and integrated display and power system.

- Functional Testing: Test each feature (timekeeping, alarms, display clarity, power usage) to ensure they work reliably.

- Environmental Testing: For clocks meant to withstand certain environmental conditions, test them under varying temperatures, humidity, and lighting.

10. Refinement and Final Adjustments

- User Experience Feedback: Gather feedback on the prototype’s look, feel, and usability.

- Design Adjustments: Make necessary adjustments to improve the user experience, durability, and reliability.

- Quality Control: Ensure that the final design is consistent and meets all design, performance, and safety standards.

11. Manufacturing and Packaging Design

- Manufacturing Plan: Prepare the design files and materials for mass production. This includes finalizing the PCB design, sourcing components, and setting up the production line.

- Packaging: Design the packaging to protect the clock during transport, and make it visually appealing for retail sales.

By following these steps, you can create a digital clock that balances functionality, aesthetics, and ease of use, making it appealing and practical for its target audience.